Drawers: how to illuminate them with LEDs?

Drawers: before selecting products or planning an installation, it is essential to understand the principles that govern lighting in confined spaces. The goal is to achieve uniform, glare-free light that accurately reveals contents without creating deep shadows or dark zones. In this section, we will examine essential photometric quantities, the behavior of light in tight spaces, and the qualitative criteria that distinguish a professional installation from an amateur one.

Drawers: essential photometric quantities

The starting point for any lighting design project is understanding the units of light measurement. For illuminated drawers, three parameters are critical: luminous flux (lumens), illuminance (lux), and uniformity of distribution. Lumens indicate the total amount of light emitted by a source, such as an LED strip. However, what truly matters in practice is how much of that light actually reaches the drawer’s surface or its contents—this is measured in lux (lumens per square meter). Accurately calculating the required lux avoids undersized installations (dark drawers) or oversized ones (energy waste and glare).

Uniformity of lighting in drawers is perhaps the most overlooked yet most important aspect. An improperly placed LED strip will create a bright “track” of light directly beneath it, leaving lateral areas in partial shadow. For medium- and large-sized drawers, it is often necessary to install two parallel lighting lines or use diffuser profiles to “spread” light homogeneously across the entire surface. The LED emission angle (typically 120° for standard SMDs) plays a key role: chips with wider angles or technologies like COB (Chip-on-Board) offer a smoother light transition, reducing the “dotted” effect and improving overall uniformity.

The psychology of light in containment spaces like drawers

Beyond technical considerations, drawer lighting has a strong perceptual and psychological component. Light inside a cabinet is not only about locating objects—it also affects the perceived quality of furniture, mental organization of space, and even the pleasure of use. A cool, intense light (e.g., 6000K) can feel clinical and unwelcoming in a bedroom, whereas warm light (2700K–3000K) creates ambiance and enhances the visual appeal of materials like wood and fabrics. In kitchen or study drawers, a neutral light (4000K) instead promotes visual precision and clarity.

The Color Rendering Index (CRI or Ra) is a technical parameter with direct perceptual impact. It indicates how faithfully a light source reveals the true colors of objects compared to natural reference light. For drawers containing clothing, jewelry, work materials, or food, a high CRI (Ra > 90) is not a luxury but a necessity. It enables distinguishing between similar color shades, evaluating food freshness, or correctly matching garments. High-end LED strips from Ledpoint, such as the F52-30s-238DY2-Ca9, deliver high performance both in efficiency (110 lm/W) and light quality, making them ideal for applications where color perception is critical.

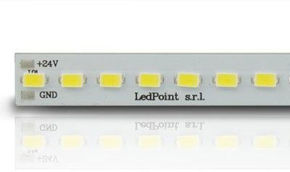

Drawers: analysis of LED strips suitable for installation in small enclosures

Choosing the right LED strip is the core of the project. The market offers a vast array of products, but not all are equally suitable for drawer lighting. Factors such as PCB physical dimensions, LED density, supply voltage, and chip type decisively determine the final result. In this chapter, we will thoroughly analyze available technologies, comparing their characteristics and suitability for installation in drawers of various types and sizes.

Drawers and LEDs: SMD vs. COB

The two main technologies for flexible LED strips are SMD (Surface-Mounted Device) and COB (Chip-on-Board). SMDs, such as the popular 2835 or 3528, are individual chips soldered onto the strip at regular intervals. They offer an excellent efficiency-to-cost ratio and great flexibility in terms of density (LEDs/meter) and power. However, up close and on reflective surfaces, they can produce a slight “dotted” effect—multiple distinct light points instead of a continuous line—making drawer lighting less elegant.

COB technology represents the evolution for applications requiring perfectly uniform and homogeneous light lines. In this approach, hundreds of micro-chips are mounted directly onto the substrate and coated with a uniform phosphor layer. The result is continuous light emission without dark gaps between chips. As stated in Ledpoint product datasheets, a COB strip like the one mentioned enables glare-free, continuous light lines with a wide diffusion angle. This makes it particularly suitable for shallow drawers or those with highly reflective interior surfaces (e.g., white laminate), where the dotted effect would be most noticeable.

Critical LED selection parameters for drawers: density, power, and voltage

LED density (expressed in chips per meter) directly affects light uniformity and illuminance. For standard drawers (40–60 cm deep), a medium density (60–120 LED/m) is often sufficient. For very deep drawers or for achieving very high light levels (e.g., tool drawers), higher densities may be required (200+ LED/m). The F52-30s-238DY2-Ca9 from Ledpoint, with its 238 LED/m, represents a high-end solution for intense, uniform lighting needs.

Linear power (W/m) and supply voltage are interdependent parameters crucial for electrical design. Most decorative and indoor LED strips operate at 12V or 24V. For projects involving multiple drawers or significant total strip lengths, selecting a 24V strip is strongly recommended. At the same power level, a 24V strip draws half the current (Amperes) compared to an equivalent 12V strip. This results in lower voltage drops along the strip (preventing light attenuation at the far end), smaller cable cross-sections, and reduced load on any controllers or dimmers. Linear power—e.g., the 15.5 W/m of Ledpoint’s COB strip—determines the total load and the required power supply capacity.

Adhesive and flexibility: ensuring durable strip mounting in drawers

The mere presence of double-sided tape on the back does not guarantee permanent adhesion, especially in environments like kitchens or garages subject to temperature fluctuations. Adhesive quality is critical. Ledpoint uses 3M 9495LE double-sided tape, known for its high initial tack and long-term durability. For a professional result, the application surface must be perfectly clean, degreased (with isopropyl alcohol), and dry before installation. For drawers subject to vibration or impacts (e.g., tool drawers), it is advisable to reinforce the adhesive with dabs of transparent silicone or nylon zip ties in non-visible areas for absolute security.

Professional design and installation of LED strips for drawers

Proper design precedes and determines installation success. This chapter provides a step-by-step methodology to correctly size the system, select auxiliary components, and execute a clean, safe, and durable installation. From wiring diagrams to physical light placement, every detail matters to achieve a system that performs flawlessly for years.

System calculation and sizing

The first step is calculating total electrical load. Sum the power of all LED strips to be powered. For example, to light five drawers each with 50 cm of 15.5 W/m strip: (0.5 m × 15.5 W/m) × 5 = 38.75 W. It is good practice to add a 20–30% safety margin to ensure the power supply does not operate at full capacity, extending its lifespan: 38.75 W × 1.25 ≈ 48.5 W. Thus, a 24V power supply with a nominal rating of at least 50–60W should be selected.

Cable management is equally important. Cables connecting the power supply to the strips—especially over long runs—must be of adequate cross-section to minimize voltage drop. For currents up to 3A over a few meters, 0.75 mm² is generally sufficient; for higher currents or longer distances, 1 mm² or 1.5 mm² is required. A common mistake is using cables that are too thin, causing reduced brightness in strips farthest from the power supply.

Placement schemes and lighting angles in drawers

Strip placement inside the drawer defines the user experience. Common configurations include:

1. High-side placement: the strip is mounted on the inside of the drawer front, pointing downward. It illuminates items near the front well but may cast shadows toward the back.

2. Central bottom placement: the strip is mounted at the center of the drawer bottom, facing upward. It provides very uniform illumination across the entire surface but is more exposed to dust and requires the bottom to remain clear.

3. Dual lines on long sides: two strips are mounted along the long sides of the drawer, facing inward. This is the most professional solution for wide drawers, as it eliminates shadows entirely and provides enveloping illumination.

For drawers with dividers or trays, consider perimeter lighting or integrating light directly under removable trays. The installation angle can be adjusted using angled profiles or simply bending the flexible strip (respecting the manufacturer’s specified minimum bend radius) to direct light exactly where needed.

Trends and innovations in illuminated drawers

The world of interior lighting is constantly evolving, and drawers are no exception. Current trends feature increasingly tight integration between light, electronics, and design, with systems that respond intelligently to user needs. In this section, we will explore the cutting edge of drawer lighting—from smart home integration to solar-powered solutions and innovative materials redefining design possibilities.

Smart home integration and intelligent control

Drawer lighting is becoming increasingly “smart.” Integration with home automation systems like Home Assistant, Apple HomeKit, or Amazon Alexa enables advanced scenarios: kitchen drawers automatically illuminate when returning home in the evening, or workshop drawer lights switch to maximum brightness when motion is detected in the garage. This requires dimmable LED strips connected to Wi-Fi or Zigbee controllers, such as many models available in Ledpoint’s catalog.

A high-design trend is gesture or touch activation. Capacitive sensors integrated into the drawer front or handle activate the light as a hand approaches, creating a magical, switch-free interaction. These sensors can be paired with a time-delay module that keeps the light on for a few seconds after closing the drawer, assisting the user in placing items. Pairing with RGB or RGBW LED strips enables dynamic lighting, where color changes based on content (e.g., blue for linens, warm light for cutlery) or mood.

Sustainability and alternative power sources

Environmental awareness is driving innovation toward ultra-low-consumption and energy-autonomous solutions. LED strips are already highly efficient, but pairing them with premium-efficiency power supplies (energy class >90%) and occupancy sensors further reduces waste. For temporary or non-wired installations (e.g., an antique cabinet), rechargeable battery kits with magnetic activation are emerging: the light turns on only when the drawer opens and recharges via USB-C.

The true frontier lies in wireless and solar-powered systems for outdoor or very bright environments. Small integrated solar panels on furniture or walls can charge a buffer battery that powers drawer lights in garden cabinets or workshop benches. Ledpoint, with its presence at industry fairs like SICAM (International Exhibition of Components for the Furniture Industry), stays continually updated on these innovations and incorporates them into its professional offerings.

Market statistics and data

The adoption of LED lighting in residential and furniture sectors is backed by concrete data demonstrating its growth and economic significance. Statistics help contextualize the phenomenon beyond trends, revealing a mature and rapidly expanding market:

- According to recent industry reports, over 35% of high-end furniture produced in Europe in 2025 includes at least one integrated illuminated element, with 12% annual growth. Drawers are the most common integration point after display cabinets.

- Modern LED efficiency—such as Ledpoint’s offerings—has reached previously unthinkable levels. The F52-30s-238DY2-Ca9 achieves 110 lm/W. By comparison, a standard halogen lamp hovers around 12–18 lm/W. This means over 85% less energy consumption for the same light output.

- A consumer survey reveals that 78% of users consider internal cabinet lighting a “significant added value” when purchasing new furniture, and 62% report it concretely improves daily home organization.

- The service life of a quality LED strip, operated under proper temperature and power conditions, easily exceeds 30,000 hours. At an average usage of 3 hours per day, this translates to over 27 years of service, drastically reducing maintenance and replacement costs.

Solutions for every need

Ledpoint offers a technical and diversified product portfolio, capable of meeting both simple and highly professional requirements. Below is an analysis of the most suitable strips for drawer lighting, referencing technical specifications from the online catalog.

- COB LED Strip: The premium solution for absolute uniformity. With 528 chips/m, 1590 lm/m, and 15.5 W/m at 24V, it is ideal for designer drawers, display cases, or luxury bathrooms where flawless lighting is essential. 3M tape ensures perfect adhesion.

- F52-40s-0608H2 (2835 LED, 4000K): A versatile, efficient (95 lm/W) solution. Its neutral light (4000K) makes it perfect for kitchen, office, or lab drawers where accurate detail perception is key. Cuttable every 10 cm, it fits any size.

- F52-30s-238DY2-Ca9 (2835 LED, 3000K): The high-output option for maximum brightness. With 238 LED/m and 1970 lm/m, it delivers intense light for very deep drawers or for illuminating dark objects. Its warm tone (3000K) suits bedrooms and living rooms.

- F52-RGB-1080OR2 (COB RGB LED): The choice for maximum customization and creativity. Enables color changes via controller for ambiance, content coding (e.g., red for important documents), or pure fun. COB technology ensures uniform color tones.

Beyond strips, Ledpoint provides all components for a complete system: 24V power supplies in various wattages, dimming and PWM controllers for color control, clip connectors for solder-free strip joining, and aluminum profiles for structured mounting and better heat dissipation in high-power installations.

Drawers: optimizing organization with LED lighting

Equipping drawers with LED strips is an investment that pays off in functionality, aesthetics, and perceived furniture value. The key to success lies in careful design (lux calculation, color temperature selection), quality product selection (high efficiency, high CRI, reliable components like 3M tape), and precise installation (surface cleaning, correct wiring).

By leveraging Ledpoint’s technical solutions and following the in-depth guidelines in this article, professionals and enthusiasts are equipped to create drawer lighting installations that are not only technically impeccable but also aligned with the latest trends in design and smart home technology. When well integrated, lighting ceases to be an accessory and becomes an essential, indispensable part of the daily experience of our spaces—helping us keep them organized and quickly locate exactly what we need.