Advanced Insights into 2835 LED Wire Technology: Au and Ag Wire Connections

In the rapidly evolving world of LED lighting, the 2835 SMD (Surface-Mount Device) LED stands out due to its compact size and high efficiency. This article delves into the specifics of wire connection technologies used in these LEDs, focusing on gold (Au) and silver (Ag) wires, and their alloys. Additionally, we will explore the impact of these materials on the LED's performance, especially under rigorous thermal cycling conditions.

Wire Connection Technologies in 2835 LEDs

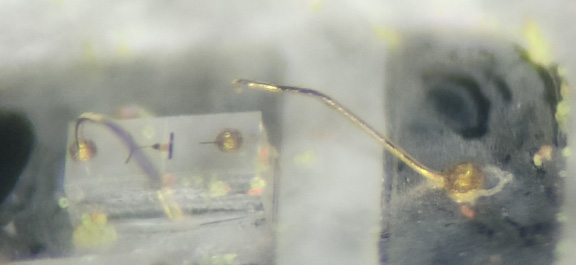

The wire bonding technique used in 2835 LEDs is a critical factor that determines the electrical and thermal performance of the LED. Here, we focus on two primary types of wire materials:

Gold (Au) Wires: Gold is highly favored in LED manufacturing due to its excellent electrical conductivity (2.44×10−8 Ω⋅m) and outstanding resistance to oxidation and corrosion. These properties ensure minimal energy loss and a stable connection over the LED’s lifespan.

Silver (Ag) Wires: Silver boasts the highest electrical conductivity (1.59×10−8 Ω⋅m) among all metals and shares similar resistance characteristics to gold. It is often used as a cost-effective alternative to gold, providing comparable performance at a lower price point.

Alloys (Au-Ag Mix): To leverage the benefits of both metals, alloys composed of gold and silver are sometimes used. These alloys aim to strike a balance between performance and cost, offering improved mechanical properties and thermal stability.

We are going to report tests made from two different supplier: supplier A and supplier B.

Performance Differences Based on Wire Material

The performance of these wires is typically evaluated through thermal cycle testing, which simulates the environmental stress LEDs might encounter in real-world applications.

Thermal Cycle Testing Protocol:

Setup: LEDs are subjected to extreme temperature fluctuations ranging from -40℃ to 100℃. Each cycle consists of maintaining the temperature at -40℃ for 15 minutes, followed by a rapid 10-second transition to 100℃, where it holds for another 15 minutes. This process tests the durability and reliability of the wire bonds under repeated thermal stress.

Supplier A checked LEDs after: 880 cycles, 160 cycles, 240 cycles, 320 cycles, 400 cycles, 480 cycles, 560 cycles.

Supplier B checked LEDs after: 100 cycles, 200 cycles, 300 cycles, 400 cycles, 500 cycles, 600 cycles, 700 cycles, 800 cycles.

The temperature of -40°C is certainly difficult to reach in real situations while the temperature inside the LED can easily reach 100°C

Tests results

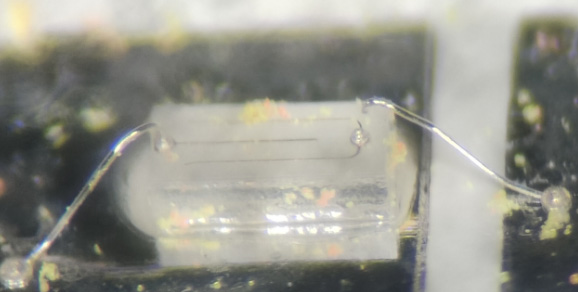

Supplier A | ||

|

|

|

99.99%Au 0.8mil (20 um) bonding wire | 20%Au 0.9mil (23 um) alloy wire | 98%Ag 0.9mil (23 um) bonding wire |

2 led no good after 560 cycle | 2 led no good after 480 cycle | 3 led no good after 400 cycle |

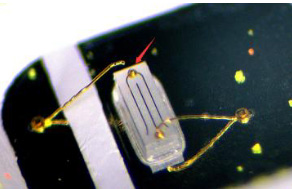

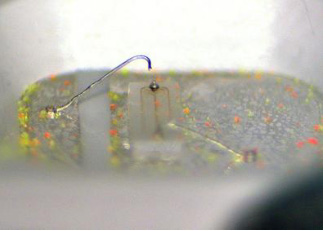

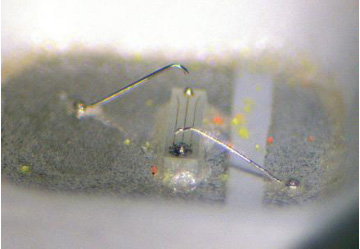

Supplier B | ||

|

|

|

Gold wire (Au) 20um | Alloy wire 23um | Alloy wire 20um |

1 led no good after 800 cycle | 2 led no good after 700 cycle | 3 led no good after 300 cycle |

Conclusion

Choosing the right wire material in 2835 LED technology is crucial for optimizing performance and longevity. Gold wires remain the best choice for applications requiring the most reliability and efficiency. Silver wires provide a valuable alternative, especially where cost considerations are paramount. The development of gold-silver alloys represents an innovative approach, offering a compromise between performance and expense. Understanding these distinctions helps manufacturers tailor their LED products to meet specific demands, ensuring both performance and durability in challenging environments.

Another important consideration is the wire diameter, which plays a crucial role in LED durability. In fact, the performance of Supplier B's LEDs shows a significant difference between the 23 µm and 20 µm alloy wires.

A final conclusion can be drawn regarding the performance differences between the two suppliers. Keeping the gold wire at 20 µm, we observed significant differences in performance between Supplier A and Supplier B.

From an application point of view, it can easily be highlighted that in applications where the LED is used outdoors, LEDs with gold wire should always be used. In fact, it is in these applications where the minimum temperature of the LED can come closest to that of the test.

All Ledpoint 2835 LED strips are manufactured with gold wires with the exception of the low-cost Honglitronic -R line.