Voltage: what it is, what it's for, and why you should pay attention to it.

In the world of LED lighting, voltage represents the fundamental parameter that determines the success or failure of an installation. Often overlooked in favor of more “visible” features such as brightness or color, voltage is actually the key element ensuring stability, efficiency, and longevity of your lighting system.

This technical and in-depth article will guide you through every aspect of voltage—from theoretical foundations to practical applications—providing concrete data and verified solutions for designers, installers, and industry enthusiasts.

Voltage: basic concepts

Voltage, or electric potential difference, represents the difference in electric potential between two points in a circuit. In LED lighting, this parameter determines how much energy is available to power the light-emitting diodes. Conceptually, voltage can be compared to pressure in a hydraulic system: the higher the pressure, the greater the ability to move water (current) through pipes (conductors).

Technical definition and units of measurement

Voltage is measured in volts (V) and represents potential energy per unit of charge. In LED systems, the most common values are 12V, 24V, and increasingly, 48V. Each value has specific characteristics that make it suitable for certain applications. For example, a 12V system is generally safer for use in damp or low-voltage environments, while 24V and 48V systems offer greater efficiency for long-distance or high-power installations.

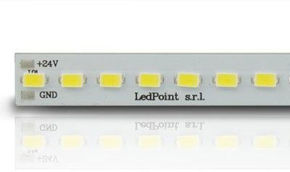

The operating voltage of an LED strip is not arbitrary but stems from the characteristics of the individual LEDs that compose it. Most SMD (Surface-Mount Device) LEDs operate at voltages between 2.5V and 3.5V but are connected in series and/or parallel to achieve standardized operating voltages. This design directly affects many practical aspects, from the maximum installation length without voltage drop to the appropriate choice of power supply.

Voltage, current, power, and Ohm’s law

To fully understand the role of voltage, it is essential to consider it in relation to two other fundamental parameters: current (measured in amperes, A) and power (measured in watts, W). The relationship among these quantities is described by Ohm’s Law (V = R × I) and the power formula (P = V × I).

Consider a practical example with real-world data: the LED strip F52-40s-0608H2 available on Ledpoint, operating at 24V with a power consumption of 14.4 W/m. Using the formula P = V × I, we can calculate the required current per meter: I = P / V = 14.4W / 24V = 0.6A/m. For a 5-meter installation, the total current will be 3A. This calculation is essential for correctly sizing the power supply and connecting cables.

Table 1: relationship between voltage, current, and power in common LED systems

| LED Strip Type | Voltage (V) | Power per Meter (W/m) | Current per Meter (A/m) | Recommended Max Length |

|---|---|---|---|---|

| Standard LED 12V | 12 | 9.6 | 0.8 | 5 meters |

| High-Efficiency LED 24V | 24 | 14.4 | 0.6 | 10 meters |

| COB LED 24V | 24 | 15.5 | 0.645 | 8 meters |

| High-Power LED 48V | 48 | 28.8 | 0.6 | 15 meters |

The importance of correct voltage for safety

Choosing the appropriate voltage is not only a matter of technical efficiency but also a critical safety consideration for the installation. Low-voltage systems (such as 12V or 24V) are generally classified as “SELV – Safety Extra-Low Voltage” under IEC/EN 61347 standards, significantly reducing the risk of electric shock in case of accidental contact.

However, it is crucial to emphasize that low voltage does not automatically mean zero risk. A 12V system carrying high currents (e.g., 20A over a 25-meter run) can still generate significant heat in the conductors, posing potential overheating and fire hazards if cables are not properly sized. Therefore, voltage selection must always consider the specific application context, balancing safety, efficiency, and cost.

12V, 24V, and 48V voltage: comparative analysis

In the LED lighting ecosystem, the choice between 12V, 24V, or 48V represents a crucial technical decision that affects every aspect of the project—from initial costs to long-term maintenance. Each configuration offers specific advantages and limitations that make it more suitable for certain applications.

12V systems: versatility and safety for domestic applications

12V systems dominated early generations of LED strips thanks to their widespread availability of power supplies and the inherent safety of low voltage. This configuration is particularly suitable for residential applications where installation lengths rarely exceed 5 meters, such as shelf lighting, furniture outlines, or decorative effects in niches.

Technically, 12V systems have a significant limitation: voltage drop occurs earlier compared to higher-voltage systems. This phenomenon, caused by conductor resistance, results in reduced brightness toward the end of the strip farthest from the power source. For a 1.5mm² copper cable, acceptable voltage drop (less than 3%) limits 12V installations to approximately 5 meters total length. Exceeding this threshold requires multi-point feeding or larger conductor gauges, increasing complexity and cost.

Despite these limitations, 12V systems remain important in specific applications, especially where safety is a priority (damp areas, proximity to combustible materials) or where integration with existing 12V systems is required, such as many automotive or marine installations.

24V voltage: the optimal compromise for most professional applications

24V voltage represents the de facto standard for professional LED lighting applications, offering the best balance of safety, efficiency, and design flexibility. Analysis of Ledpoint product specifications reveals that most professional LED strips—such as the F52-40s-0608H2 and COB strips—are optimized to operate at 24V.

The main advantage of 24V systems lies in reduced current for the same power output. Comparing two 150W installations: at 12V, it requires 12.5A, while at 24V it only needs 6.25A. This current reduction has significant implications:

lower voltage drop: for the same conductor gauge, voltage drop is four times lower at 24V compared to 12V (proportional to the square of current);

more efficient power supplies: modern switching power supplies operate at higher efficiencies (85–92%) at 24V compared to equivalent 12V versions;

reduced wiring costs: lower current allows smaller conductor gauges for the same distances, yielding significant savings on large-scale installations.

Table 2: performance and limitation comparison across different supply voltages

| Parameter | 12V system | 24V system | 48V system | Unit |

|---|---|---|---|---|

| Max length without voltage drop (>3%) | 5 | 10 | 20 | Meters |

| Current for 150W | 12.5 | 6.25 | 3.125 | Amps |

| Recommended cable gauge for 10m @150W | 2.5 | 1.5 | 1.0 | mm² |

| Typical power supply efficiency | 80–85% | 85–92% | 90–94% | Percentage |

| Relative power supply cost | 1.0x | 1.1x | 1.3x | Factor |

| Typical applications | Residential, automotive, marine | Commercial, retail, offices | Industrial, architectural, outdoor | - |

48V voltage: the evolution for professional and industrial installations

48V systems represent the technological frontier in professional LED lighting, offering significant advantages for large-scale, long-distance, and high-power installations. This configuration is rapidly gaining popularity in architectural and industrial lighting sectors.

The primary advantage of 48V is the dramatic reduction in voltage drop losses, enabling installations up to 20–25 meters from a single power feed. This translates into simpler wiring, lower installation costs, and greater flexibility in lighting design. Moreover, 48V systems operate at even lower currents for the same power, further reducing conductor size and improving overall system efficiency.

Technologically, 48V systems benefit from convergence with other industries that have already adopted this voltage as a standard—such as telecommunications, data centers, and electric vehicles. This synergy has accelerated the development of high-efficiency, high-reliability components, making 48V systems increasingly competitive even for high-end commercial applications.

Problems caused by inappropriate voltage and practical solutions

Choosing an inappropriate voltage or mismanaging electrical parameters in an LED system can trigger a cascade of technical problems that compromise performance, lifespan, and safety. Understanding these issues and their solutions is essential for anyone designing, installing, or managing LED lighting systems.

Voltage drop: causes, effects, and mitigation strategies

Voltage drop is the most common issue in LED systems, especially in long-distance installations. This phenomenon occurs when conductor resistance causes a progressive voltage decrease along the current path, resulting in non-uniform brightness with dimmer areas toward the end farthest from the power source.

Voltage drop (ΔV) can be calculated using the formula: ΔV = 2 × L × I × R, where L is conductor length in meters, I is current in amps, and R is resistance per meter of the conductor (in Ω/m). For a 24V LED strip drawing 14.4W/m (0.6A/m) over 10 meters, powered by a 1.5mm² copper cable (R ≈ 0.012 Ω/m), the total voltage drop (round-trip) would be: ΔV = 2 × 10m × 6A × 0.012 Ω/m = 1.44V. This represents a 6% loss—exceeding the recommended 3% threshold for optimal performance.

Strategies to mitigate voltage drop include:

multi-point feeding: connecting the LED strip at multiple points along its length to reduce current travel distance through conductors;

increasing conductor gauge: using larger-diameter cables (e.g., upgrading from 1.5mm² to 2.5mm²) to reduce resistance;

higher-voltage systems: choosing 24V or 48V LED strips instead of 12V to reduce current at equal power;

distributed power supplies: placing multiple power supplies along the installation instead of a single central unit.

Overvoltage and undervoltage: impact on LED lifespan

Deviations from nominal voltage pose serious risks to LED system reliability and longevity. While modern LED drivers include protection circuits, prolonged exposure to incorrect voltages significantly accelerates component degradation.

Overvoltage (voltage above nominal) causes an exponential increase in LED current, leading to overheating that rapidly degrades phosphors and reduces luminous efficacy. Industry studies show that a 10% voltage increase above nominal can reduce LED lifespan by up to 50%. Conversely, undervoltage (voltage below nominal) prevents LEDs from achieving optimal performance, causing lower luminous efficiency and possible flicker effects that can be visually uncomfortable or even hazardous in work environments.

Table 3: effects of voltage deviations on LED performance

| Voltage deviation | Current variation | Brightness variation | Lifespan impact | Junction temperature |

|---|---|---|---|---|

| +5% | +15–20% | +10–15% | 30% reduction | +8–10°C |

| +10% | +30–40% | +20–25% | 50–60% reduction | +15–20°C |

| -5% | -15–20% | -15–20% | +10% increase | -5–8°C |

| -10% | -30–40% | -30–35% | +25% increase | -10–15°C |

Incompatibility with power supplies and controllers

A frequently underestimated issue is incompatibility between LED strip voltage and power supply characteristics. An undersized or mismatched power supply can cause instability, reduced efficiency, and even premature failure. Power supply selection must consider not only nominal voltage but also total required power, regulation type (constant voltage vs. constant current), and environmental conditions (temperature, humidity).

For dimmable LED systems, harmony among voltage, power supply, and controller is especially critical. Many controllers are designed for specific voltages and may not function properly (or at all) if connected to incompatible systems. For instance, a controller designed for 12V connected to a 24V strip might fail to adequately regulate current, resulting in nonlinear dimming or unstable behavior.

The optimal solution lies in selecting compatible system components, preferably from the same product line or manufacturer. Ledpoint offers integrated solutions where LED strips, power supplies, and controllers are designed to operate synergistically, ensuring optimal performance and simplifying design and installation.

Sizing and practical calculations for professionals

Proper sizing of an LED system is a methodical process that integrates electrical, thermal, and application considerations. This chapter provides practical tools and detailed procedures to ensure every installation meets performance requirements while maintaining efficiency and reliability over time.

Total power calculation and power supply selection

The first step in sizing any LED system is determining the total required power. This value is calculated by multiplying the strip’s power per meter (available in technical specifications) by the total installation length. To ensure safety margin and system longevity, it is advisable to add a 20–30% buffer to the calculated power.

Consider a practical example: an office lighting installation using 25 meters of F52-40s-0608H2 LED strip at 24V and 14.4W/m. Total required power: 25m × 14.4W/m = 360W. Adding a 25% safety margin: 360W × 1.25 = 450W. The selected power supply should therefore have a nominal rating of at least 450W at 24V.

Power supply selection involves more than just power and voltage. Other critical factors include:

energy efficiency: power supplies with 80 Plus certification or equivalent offer higher efficiencies (>90%), reducing energy consumption and heat dissipation;

power factor (PF): higher values (>0.9) indicate better use of apparent power, important for large commercial installations;

built-in protections: quality power supplies include short-circuit, overload, overtemperature, and overvoltage protection;

warranty and reliability: power supply lifespan should match that of the LEDs (typically 50,000 hours).

Conductor sizing and protection calculations

Conductor sizing is essential to ensure safety and optimal performance. Undersized conductors cause excessive voltage drop and overheating, while oversized ones unnecessarily increase cost and installation complexity.

Minimum conductor cross-section (in mm²) can be calculated using the formula: S = (2 × L × I × ρ) / ΔV, where L is conductor length in meters, I is current in amps, ρ is copper resistivity (0.0175 Ω·mm²/m), and ΔV is maximum allowable voltage drop in volts.

For a 24V LED strip at 15.5W/m (0.645A/m) over 8 meters, powered from a central point (so L = 4m per side), with total current of 5.16A and maximum 3% voltage drop (0.72V): S = (2 × 4m × 5.16A × 0.0175 Ω·mm²/m) / 0.72V = 1.0 mm². In practice, a standard 1.5mm² cable would be selected—the next available larger size.

Table 4: conductor selection guide for various currents and lengths

| Current (A) | Length 5m | Length 10m | Length 15m | Length 20m |

|---|---|---|---|---|

| 3A | 0.75 mm² | 1.0 mm² | 1.5 mm² | 2.5 mm² |

| 6A | 1.0 mm² | 1.5 mm² | 2.5 mm² | 4.0 mm² |

| 10A | 1.5 mm² | 2.5 mm² | 4.0 mm² | 6.0 mm² |

| 15A | 2.5 mm² | 4.0 mm² | 6.0 mm² | 10.0 mm² |

Thermal management and environmental considerations

Thermal management is a critical yet often overlooked aspect in LED systems. While LEDs themselves are efficient, a significant portion of electrical energy (typically 15–30%) is still converted into heat that must be dissipated to maintain expected performance and lifespan.

LED junction temperature (Tj) is the key parameter determining lifespan and luminous flux maintenance. For every 10°C increase above nominal temperature, LED lifespan roughly halves (Arrhenius Law). In Ledpoint products like the COB strip rated for -10°C to +45°C operating ambient temperature, these specs indicate the ambient range within which the strip maintains declared characteristics.

Effective thermal management strategies include:

aluminum profiles: use extruded profiles with adequate surface area to dissipate generated heat;

spacing from surfaces: ensure adequate airflow behind LED strips, especially in recessed or enclosed installations;

derating in hot environments: reduce nominal power by 10–20% in environments above 30°C;

temperature monitoring: for critical installations, consider using temperature sensors with automatic current regulation.

Future trends and technological innovations in LED voltage

The LED lighting industry is continuously evolving, with innovations redefining design and installation parameters. Understanding these emerging trends is essential for professionals aiming to deliver cutting-edge solutions and prepare for future technical challenges.

Shift toward 48V and beyond: industry implications

The transition to 48V systems is accelerating in response to growing demand for longer, more efficient, and flexible installations. This trend, also mentioned in Ledpoint.it resources, is driven by converging factors: the need to reduce installation costs in large-scale projects, integration with renewable energy systems (which often operate at 48V), and compatibility with emerging power electronics standards.

Technical implications of this shift are significant. 48V systems enable:

installations up to 25–30 meters from a single power feed, revolutionizing architectural lighting design possibilities;

up to 60% reduction in wiring costs compared to equivalent 12V systems, thanks to smaller conductors and fewer multi-feed points;

simpler integration with intelligent energy management systems and alternative power sources;

better regulation and stability due to reduced sensitivity to voltage drops.

Industry research indicates that by 2028, 48V systems will represent over 35% of the professional LED lighting market, growing at an annual rate of 12–15% compared to the overall market’s 7–8% growth.

Smart lighting and digital control systems

Integration between voltage and intelligent control systems is creating new possibilities for adaptive and efficient lighting. Modern control systems go beyond simple intensity regulation—they constantly monitor electrical parameters like voltage, current, and power, dynamically adjusting performance to optimize efficiency and lifespan.

Innovations in this area include:

power supplies with digital communication (DALI, 0–10V, DMX) enabling precise control and remote monitoring of electrical parameters;

automatic voltage detection systems that adapt output characteristics to the specific LED strip connected;

thermal compensation algorithms that automatically adjust current based on sensed temperature, maintaining constant light output and extending lifespan;

integration with building management systems (BMS) for holistic energy control at the building level.

These technologies transform voltage from a static design parameter into a dynamic variable within an intelligent lighting system, opening new avenues for energy efficiency and lighting personalization.

Advancements in semiconductor materials and their voltage impact

Progress in semiconductor technology is profoundly influencing LED operating characteristics, including optimal operating voltage. The shift from gallium arsenide phosphide (GaAsP)-based LEDs to indium gallium nitride (InGaN) has already enabled lower junction voltages for various emission wavelengths.

Recent trends include:

direct low-forward-voltage LEDs (Vf) operating below 2.5V, enabling longer series configurations at the same supply voltage;

LED chips with tighter voltage tolerances, improving color uniformity and reducing the need for binning (sorting by similar characteristics);

wider bandgap materials such as gallium nitride (GaN) on silicon substrates, promising further cost reductions and performance improvements;

quantum dot structures enabling precise emission spectrum tuning without significant changes to operating voltage.

These innovations translate into products with enhanced specifications—such as LED strips offering efficiencies above 110 lm/W with stable supply voltages and tight tolerances.

Ledpoint products optimized for every voltage requirement

Ledpoint offers a comprehensive range of solutions for every voltage requirement—from low-voltage residential applications to high-efficiency professional and industrial installations. This chapter explores the technical features and optimal applications of available products, providing concrete guidance for selection based on specific design requirements.

24V COB LED strip: maximum uniformity for premium applications

The 24V COB (Chip-on-Board) LED strip is the ideal solution for applications where light uniformity and the absence of a “dotted” effect are paramount. As described in Ledpoint specifications, this technology places a high density of LED chips (5280 over 10 meters) directly onto the substrate, covered by a uniform phosphor layer that creates a continuous, homogeneous light line.

Notable technical features of this strip include:

high luminous efficacy: 1590 lm/m with 110 lm/W efficiency—among the highest available;

excellent color rendering: typical CRI >90, essential for retail, museum, or color-critical applications;

wide beam angle: 120° or greater, ensuring uniform light distribution without shadows;

full dimmability: compatible with most standard industry control systems;

precision cutting: cuttable every 4.55cm (24 chips), allowing maximum flexibility for custom installation lengths.

Ideal applications for the 24V COB strip include display cases, countertops, museums, high-end commercial environments, and any setting where light quality and uniformity are critical. The 24V voltage also allows installations up to 8–10 meters from a single feed, significantly simplifying wiring compared to equivalent 12V systems.

F52-40s-0608H2 24V LED strip: the optimal performance/price balance

The F52-40s-0608H2 LED strip is the ideal choice for commercial and residential applications seeking the best balance between performance, reliability, and cost. Operating at 24V with 14.4W/m, this strip uses high-quality 2835 LEDs offering excellent efficiency (95 lm/W) and long lifespan.

Distinctive features of this product:

high-efficiency 2835 LEDs: proven technology with excellent thermal performance and longevity;

3-step color temperature: 4000K with tight tolerance, ensuring chromatic uniformity across production batches;

3M 9495LE double-sided tape: professional-grade adhesive ensuring reliable bonding even on curved or irregular surfaces;

cut every 10cm: installation flexibility with clearly marked and defined cut points;

pre-soldered power cables: installation time savings and guaranteed optimal electrical connections.

This strip is particularly suited for offices, retail stores, hotels, and residential environments requiring quality lighting at a reasonable investment. The 24V voltage supports installations up to 10 meters without significant voltage drop, while the 95 lm/W efficiency ensures low energy consumption without compromising light quantity or quality.

Custom solutions and specialized technical support

Beyond standard products, Ledpoint offers custom solutions for special projects with specific voltage, power, or size requirements. This flexibility is especially valuable for large-scale projects, installations with unique dimensional constraints, or applications in extreme environmental conditions (high/low temperatures, humid environments, etc.).

Specialized technical support available through Ledpoint includes:

pre-design consultation: assistance in selecting the optimal voltage based on application-specific requirements;

sizing calculations: support in determining appropriate power supplies, conductors, and protections for each installation;

long-distance solutions: strategies for installations exceeding recommended maximum lengths, such as multi-point feeding or voltage boosters;

control system integration: assistance in selecting and configuring compatible controllers, dimmers, and automation systems;

thermal analysis: evaluation of heat dissipation needs to ensure optimal performance and long-term reliability in all operating conditions.

This holistic approach—combining high-quality products with specialized technical support—ensures every installation not only meets immediate requirements but also delivers reliable, optimal performance over the long term.

Voltage: strategic importance in LED systems

Voltage represents the fundamental parameter influencing every aspect of an LED lighting system—from initial performance to long-term durability, from installation costs to operational efficiency. Through this in-depth analysis, we have explored how the choice among 12V, 24V, and 48V is not merely technical but a strategic decision determining the overall project success.

24V systems emerge as the optimal standard for most professional applications, offering the best balance of safety, efficiency, and flexibility. However, the growing adoption of 48V systems for long-distance and high-power installations is redefining design parameters, offering new possibilities in architectural and industrial lighting.

Regardless of the chosen voltage, the fundamental principles remain unchanged: careful planning, proper sizing of all components, and a deep understanding of the interactions among voltage, current, and power are essential for creating safe, efficient, and durable installations. Ledpoint products—designed with clear technical specifications and tight tolerances—provide a solid foundation for lighting systems that meet and exceed expectations, today and into the future.